Introduction

HXWR-11S steel wire rope tester is the latest NDT testing instrument based on the principle of magnetic leakage, it can real-time test the internal and external wire rope defects such as broken wire, corrosion, deformation, loose. It is widely used in industries of hoisting machinery, coal mine hoist, oil field, mining machine, elevator, cableway, port machiery, cable bridge, wharf, ship-building, war industry, water conservancy, electric power, railway, construction and other industries relater with testing wire.

Principle

HXWR-11S wire rope tester adopts magnetic leakage method to make testing. When the wire rope passes through the transducer, the permanent magnet steel of transducer magnetizes rope axially and deeply until it is saturated fully. Defects such as broken wire and wear synchoronously produce magnetic leakage field and mangnetic fulx change. Mangetic signal spread to space. And the spreading signal is concentrated by poly cooper. And the spreading singal is converted to voltage. Then it is changed it to digital values by wide angle hole array element group. Then compress and send digital signal to computer. Decompress the data real time by this three dimensonal mathematical model software. Then specific quantitative number will show the internal and external of broken wire, corrosion, wear, metallic cross-sectioinal area changes of the wire rope. Finally, in accordance with the current standard, the system generates a report of safety and service life of wire rope.

Features

Adopts virtual instrument technology.

Transducer adopts electromagnetic qualitative, quantitative and origentation methods to test the online steel wire rope with NDT method.

This machine can test broken wires, corrosion, wear, loose strands, jump wire cross-sectional area, deformation and anomalies of wire rope.

In accordance with the regulation of national metrology and the national production safety law, each machine was inspected by the third party according to American ASTM1571 standards and was awarded with test report and leagal qualifications.

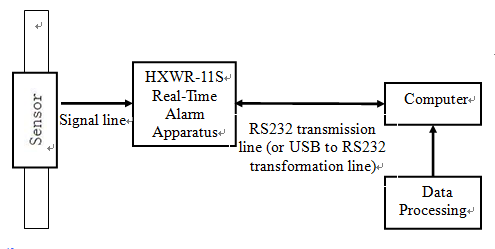

Combines with international advanced HXWR magnetic sensor with independent research and development data coleection module, this instrument can store the data directly into computer through RS232 and USB bus driver.

High strength permanent magnet steel excitation is designed with the principle of magnetic flux leakage and magnetic fulx change. This principle can achieve comprehensive detction on crack, rust and rod wear.

Using wide angle hall array element group to achieve no leakage detection.

Centered guide sleeve in transducer ensure that signal collecting is stable.

Software can achieve data acquisition and control, data analysis, data display and data storage.

AD analog-to- digital conversion, wavelet transform, noise rejection and other powerful features.

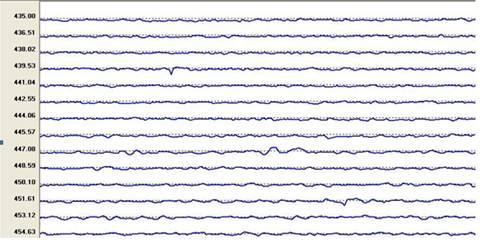

Visual characteristics which can continuously and dynamically oberve the change of data signal and show the results real-time.

When testing value exceeds the set value, it will make real-time sound and light alarm. It is humanized design, practical and reliable.

Automatic evalutation function can help inspector anyalyze the results conveniently and automatically.

Manual analysis function can guarantee the accuracy of test results and avoid missed detection.

Partial defects show the percentage of section in total area.

Testing waveform figure can be printed at any time.

The analysis and evaluation of the original results can be generated a report in word format and displayed intuitively.

Easy operation, user can operate it in several miniutes.

Specifications

| Detection Range of Rope Diameter | Φ1.5 - 300 mm (Various diameter wire rope need use various transducer) |

| Detection Efficiency | 0.0 - 6.0 m/s (Relative speed between transducer and wire rope) |

| Best Detection Efficiency | 0.3 - 1.5 m/s |

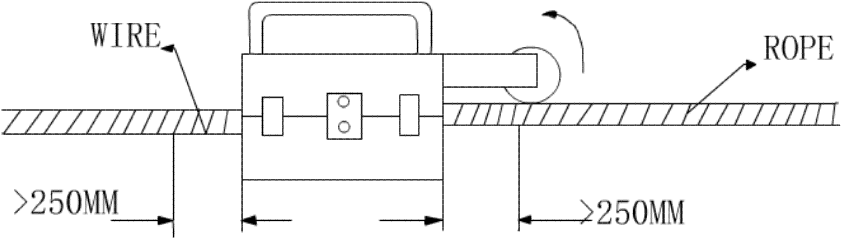

| Best Gap Between Transducer Guide Sleeve and Wire Rope | 2 - 6 mm |

| Allows Gap | 0 - 15mm |

| Local Flaw ( LF ) | |

| Broken Wire Qualitative Detection Accuracy | 99.99% |

| Broken Wire Qualitative Detection Accuracy | Monofilament miscalculation |

| No error quantitative detection for the number of focused broken wires on single point | ≥ 92% for more than 100 times |

| Loss of Metallic Area ( LMA ) | |

| Sensitivity Error | ± 0.055% |

| Accuracy Error | ± 0.2% |

| Location ( L ) detection capabilities | |

| Length Indication Error | ± 0.2% |

| Power sSupply | 5V of computer battery |

| Transducer Weight | Common Specifications <10kg |

| Temperature | -20 °C ~ 50 °C |

| Pressure | 86 ~ 106Kpa |

| Relative Humidity | ≤ 85% |

Software Windows |

Test Report |

Deterioration Analysis

| Transducer Type | Rope Diameter(mm) |

| 1 | 10 |

| 2 | 15 |

| 3 | 20 |

| 4 | 25 |

| 5 | 30 |

| 6 | 35 |

| 7 | 40 |

| 8 | 45 |

| 9 | 50 |

| 10 | 56 |

| 11 | 60-69 Customized |

| 12 | 70-79 Customized |

| 13 | 80-89 Customized |

| 14 | 90-99 Customized |